Address: 563 Nui Thanh, Hoa Cuong Ward, Da Nang City

Tel: 0916.860.231 - 0905.160.231 - Website: davitecco.com - Email: info@davitecco.com

Warehouse: Thach Nham Dong Village, Ba Na Commune, Da Nang City

Promotion price Contact

Condition of productsIn stock

Characteristics:

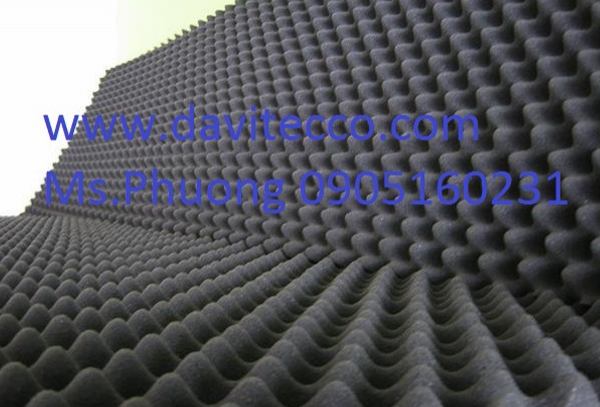

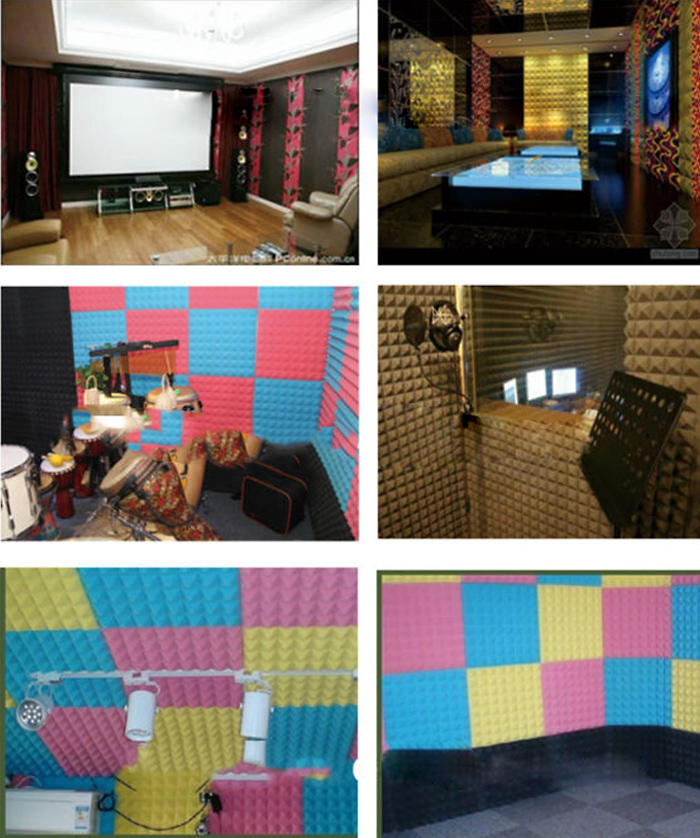

Egg crate foam (also known as pyramid foam) is sound-absorbing foam produced from shaped acoustic foam with a surface designed like egg trays. It works to absorb and reduce sound, especially in the mid and treble ranges. In addition, egg crate foam is made from professional-grade polyurethane acoustic foam with high density and a “egg crate” surface design that increases surface area, thereby delivering optimal sound absorption performance. Complex acoustic foam panels absorb sound at low, mid, and high frequencies, making them perfect for recording or listening environments. They are not only found in recording studios and the private listening rooms of renowned audiophiles but are also widely used in auditoriums, hotels, theaters, and nightclubs.

Unlike many other sound-absorbing materials, egg crate foam absorbs sound exceptionally well across multiple frequency ranges, with absorption coefficients ranging from 0.8 to 1.05 Hz.

Egg crate foam is an effective solution for improving sound absorption by reducing echoes and reverberations. This product is ideal for any type of acoustic application.

Features and Benefits:

Lightweight material, easily attachable to various surface types.

Easy to install and can be cut into custom shapes and sizes.

Safe for use in clean rooms, medical equipment environments, and computer rooms.

Made from polyurethane foam with a UL94 HF-1 fire-resistance rating. Fire safety should be evaluated depending on the materials it may come into contact with before use.

Applications:

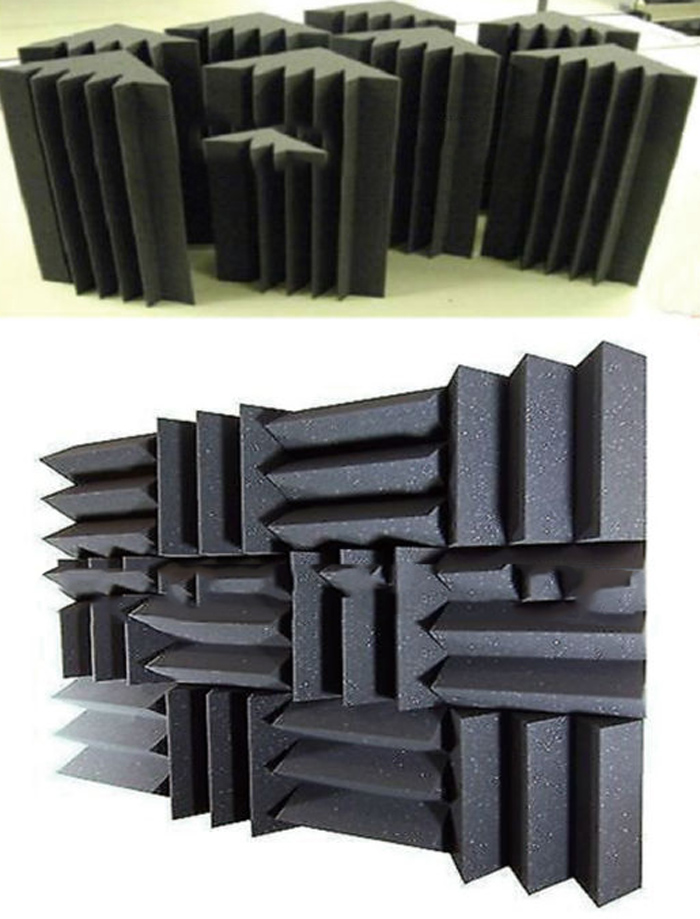

Egg crate foam provides excellent sound absorption and diffusion thanks to its complex surface, offering a larger sound-diffusion area compared to other soundproofing materials. The pyramid-style egg crate surface enhances its ability to absorb sound energy from all angles.

Specifications

Polyurethane Acoustic foam

1.Pass ROHS test

2.Free sample

3.Color:grey,black

4.Can be fire-proof

Name: China made Egg crate High density fireproof Polyurethane Acoustic foam

|

Material: |

PU Polyurethane |

|

Density: |

20-30 KGCubic meter |

|

Size: |

2000(L)x1000(W)x15-90(T)MM |

|

Conventional color: |

Black White Red Yellow Color can be customized |

|

Product performance: |

Wave Pointed cone pyramid fireproof, with glue Shock Sound-absorbing lnsulation |

|

Application: |

Between mechanical test Conference room KTV Sound insulation room Between broadcast……. |

|

Packing: |

Woven bag packaging |

Wave sound absorbing sponge is mainly based on material PU .there are many advantages such as high fireproofing ,strong air permeability and feeling soft. the main market covers many countries such as Europe, America ,the Middle East and so on .they are mainly used in KTV ,hotel, building, public place of entertainment ,auto manufacture , machine and so on.

.

Promotion

Other products

Viewed products

Specializing in Mineral wool products, Rockwool, Glass wool, Insulation products, Vulcanized rubber, Insulation products, Refractory brick products, Industrial ventilation, Valves and pipe fittings, Copper pipes & copper pipe fittings, Burners & burner accessories

Currently, the price of Ceramic fiber in sheet form is a topic that many people ...

Power and Control Systems are two essential components in electrical systems, both in industrial and residential applications. They play a crucial role in providing energy and controlling machinery, equipment, and processes in various sectors like manufacturing, processing, and other industries.

A Power System refers to the electrical system that provides and distributes electrical energy to drive motors, machines, and other equipment. It is primarily used to power motors, heating systems, pumps, fans, compressors, and more.

Power Supply: This can be from the national grid or self-generated power (like generators).

Transformer: Converts voltage from high to low or vice versa based on the requirements of the equipment.

Motor Control Center (MCC): A distribution panel that supplies electrical energy to various machines and motors. It includes protection devices, measurement tools, and controllers.

Electric Motors: These convert electrical energy into mechanical energy to operate machines like pumps, fans, compressors, conveyor belts, etc.

Fuses and Circuit Breakers: Protect the system from overloading and short circuits.

Providing energy to industrial machines and production lines.

Operating devices like pumps, fans, compressors, and conveyors.

Powering mechanical equipment in various industries, such as food processing, textile manufacturing, and heavy machinery.

A Control System is the part of an electrical system that monitors, controls, and manages the operation of electrical devices and machinery. The main goal of the control system is to ensure that equipment works accurately, safely, and efficiently.

Automatic Control:

PLC (Programmable Logic Controller): Widely used in industrial applications, PLCs are programmable devices that automate processes like production, machinery, and equipment control. They offer precise and efficient automation.

SCADA (Supervisory Control and Data Acquisition): A remote monitoring and control system used to manage large networks like electrical grids, water distribution, etc.

Manual Control:

Switches, buttons, mechanical controllers: These are used in simpler applications or when human intervention is required to control system operations.

Electronic Control:

Inverter Drives: Used to control the speed of motors, helping save energy and optimize performance.

Sensors and Actuators: Sensors (for temperature, pressure, position, etc.) gather data and send it to the controller, which adjusts the process accordingly.

Central Controller: This is the main unit (e.g., PLC or computer control system) that processes all control signals and commands.

Sensors: Measure factors like temperature, pressure, humidity, speed, liquid level, etc., and send this data to the controller.

Actuators: Based on signals from the controller, actuators (like valves, pumps, or motors) adjust the system by changing parameters (e.g., motor speed, opening/closing valves).

Control Panels: The interface between operators and the system, allowing for manual or automated control of the processes.

Industrial Automation: Control machines and equipment in production lines.

Energy Management in Smart Buildings: Control HVAC systems, lighting, and electrical devices.

Remote monitoring and control in large-scale infrastructure like power plants, water plants, etc.

Industries like pharmaceuticals, food processing, automotive manufacturing, and fabrication.

Power Systems provide electrical energy to machines, equipment, and mechanical devices used in industrial applications.

Control Systems monitor and regulate the operation of equipment in the power system to ensure stable, safe, and efficient functioning.

Both of these systems are essential in modern industries, helping optimize production processes, save energy, and improve product quality.

Power Systems focus on supplying and distributing electrical energy to mechanical equipment and machinery.

Control Systems focus on monitoring and controlling the operation of devices within the power system, ensuring efficient, safe, and accurate operation.

Both systems are indispensable in modern industries, ensuring that processes run smoothly, energy is used efficiently, and safety standards are met.

A wastewater and domestic water treatment system is designed to remove pollutants and contaminants from domestic or industrial wastewater, with the aim of returning clean water to the environment or reusing it. This system is crucial for environmental protection, public health, and ensuring clean water for daily use, production, and consumption.

Domestic wastewater refers to wastewater generated from daily human activities in households, residential areas, office buildings, schools, hospitals, etc. It includes wastewater from toilets, kitchens, showers, laundry, and other household activities.

Preliminary Treatment:

Objective: Remove large solid particles, debris, oils, and grease from wastewater.

Method: Use screens, grates, and settling tanks to remove coarse solids and waste.

Primary Treatment:

Objective: Remove suspended solids and organic sludge from wastewater.

Method: Use settling tanks to separate larger particles from the water.

Secondary Treatment (Biological Treatment):

Objective: Remove dissolved organic matter and microorganisms.

Method: Use microorganisms to decompose organic substances in wastewater. Common methods include aeration tanks (activated sludge) or biological filtration systems.

Tertiary Treatment (Chemical Treatment):

Objective: Remove remaining pollutants, especially nutrients like nitrogen and phosphorus.

Method: Apply chemicals to neutralize or precipitate contaminants, and possibly use filtration systems like ultrafiltration or reverse osmosis (RO).

Disinfection:

Objective: Eliminate bacteria, viruses, and pathogens that may still be present in the water after the treatment stages.

Method: Use chemicals like chlorine, ozone, or ultraviolet (UV) light for disinfection.

Reuse or Discharge into the Environment:

Objective: Provide treated water for reuse or discharge it into the environment without causing pollution.

Method: Treated water can be reused for irrigation, vehicle washing, or discharged into public drainage systems.

Industrial wastewater is generated from manufacturing and processing activities, containing chemicals, oils, heavy metals, and other pollutants.

Industrial wastewater treatment systems are typically more complex and require specialized treatment methods depending on the industry and the characteristics of the wastewater.

Environmental Protection: Wastewater treatment prevents water, soil, and air pollution, protecting ecosystems and natural resources.

Public Health Protection: Removal of bacteria, viruses, and harmful substances helps prevent diseases and ensures the health of the population.

Water Reuse: Treated water can be reused for non-potable purposes such as irrigation, cooling, or industrial processes.

Compliance with Legal Regulations: Treatment systems help facilities and residential areas comply with environmental protection laws, avoiding fines and legal issues.

A wastewater and domestic water treatment system plays a vital role in maintaining a clean and sustainable living environment. These systems remove pollutants from domestic and industrial wastewater, protecting public health and the environment, and also contributing to the efficient reuse of water.

Maintenance services for mechanical, electrical, and thermal equipment are crucial services that help ensure the stable and efficient operation of mechanical, electrical, and thermal systems in factories, enterprises, buildings, and production facilities. Maintenance not only helps prevent breakdowns but also extends the lifespan of equipment, reduces repair costs, and increases productivity.

Mechanical equipment maintenance involves machines and mechanical devices such as motors, pumps, fans, compressors, conveyors, etc. The maintenance work focuses on inspecting, adjusting, and replacing mechanical components to ensure smooth operation.

Inspecting mechanical integrity: Ensure that the equipment is not worn out, damaged, or weakened due to time.

Lubrication and cleaning: Ensure that moving parts are adequately lubricated to reduce friction and improve efficiency.

Inspecting and replacing parts: Check components like bearings, belts, gears, and drive systems, and replace them as necessary.

Alignment and adjustments: Check the accuracy of moving parts and make necessary adjustments to optimize performance.

Electrical equipment maintenance involves electrical systems, electric motors, electrical panels, control boards, and other electrical devices. The aim of this work is to ensure stable operation and prevent electrical issues such as overloading, short circuits, or sudden power outages.

Inspecting electrical systems: Check wiring, fuses, sockets, switches, and protection devices to detect faults or issues.

Inspecting and replacing electrical components: Check electric motors, electrical panels, controllers, and replace components such as capacitors, starters, or switches.

Cleaning electrical equipment: Remove dirt, dust, and check electrical connections to prevent short-circuiting or fires.

Inspecting and replacing protective devices: Regularly check protection devices like relays, fuses, and circuit breakers to ensure safety during malfunction.

Thermal equipment maintenance involves systems related to heat, such as boilers, air conditioning systems, heat exchangers, coolers, and other heat transfer equipment in factories. This maintenance helps maintain thermal energy efficiency and prevent thermal-related malfunctions.

Inspecting boiler systems: Ensure pressure, temperature, and combustion processes are stable and heat transfer is efficient.

Cleaning and maintaining heat exchangers: Remove sediment, blockages, and maintain heat exchange components to improve efficiency.

Inspecting cooling systems: Ensure that coolers or refrigeration systems are working well, with no blockages or equipment failures.

Maintaining HVAC systems: Ensure that the HVAC (Heating, Ventilation, and Air Conditioning) system operates efficiently, check filters, valves, and temperature control systems.

Extend equipment lifespan: Regular maintenance helps identify and address minor issues before they become major problems, thus extending the equipment's lifespan.

Improve operational efficiency: Maintenance ensures that equipment runs smoothly, reducing downtime in production.

Cost savings: Timely maintenance helps avoid large repair costs and minimizes downtime.

Ensure workplace safety: Regular inspection and maintenance of electrical and mechanical equipment help detect potential hazards, ensuring worker safety.

Comply with legal regulations: Factories and production facilities often have to comply with regulations regarding equipment maintenance and safety, and regular maintenance ensures compliance.

Scheduled Maintenance: Conducted according to a predefined schedule to ensure that equipment remains in good working condition.

Condition-Based Maintenance: Performed when abnormalities or issues are detected in the equipment's performance.

Emergency Maintenance: Carried out when a piece of equipment breaks down unexpectedly and immediate repair is needed to avoid operational disruption.

Maintenance services for mechanical, electrical, and thermal equipment play a vital role in maintaining the smooth operation of equipment systems in industrial sectors, helping optimize productivity, reduce costs, and ensure workplace safety. Performing regular and timely maintenance will improve work efficiency and minimize the risk of failures.